|

'Flashing EAS level indicator lamp' 'Air suspension compressor running more often than usual' 'Range Rover sinks onto it's bump stops over night' 'The air suspension takes ages to fully rise first thing in the mornings' These are all signs & symptoms of a worn air suspension compressor piston seal. One of the most common failings with the electronic air suspension system is the compressor pump and the most common cause of this failure is the piston and seal assembly. Most Land Rover dealers will tell you that your compressor is faulty and needs completely replacing costing several hundred pounds. This is not the case anymore... An alternative to replacing the complete compressor unit is to just replace the faulty Teflon piston ring. This process can be carried out in about an hour, no specialist tools are required however, moderate mechanical ability would be an advantage. It is very easy to check to see if the Teflon seal is damaged before you order, just follow the first couple of steps in the instructions below. When you get to the section about removing the 'metal plates or replacing the o'rings you can just ignore this stage. If you need instructions on how to remove the pump from the vehicle 'click here' Click here for further details & pricing:

|

|

| Fitting a new piston ring/seal to your old piston. | |

|

This

kit contains:

One Teflon piston ring/seal - pictured left One small O-ring One large O-ring |

|

Your compressor |

|

Take the 4 bolts off the top and take the top cover off - being careful of the silicon gaskets- they are not cheap. The small o-ring goes in this top valve. Remove the screw and two metal plates-be careful of their orientation, fish out the o-ring with a needle or pin and press the new o-ring into place. Clean up the check valve and replace the same way it came out. |

|

Take the top of the chamber off - again be careful with the gaskets: Remove the large o-ring from the groove in the bottom of the head, and replace with the new one. |

| If you are just checking to see if your Teflon seal is damaged you do not need to proceed past this point, you should be able to inspect the seal for damage from here . | |

|

Take the 3 bolts of the pump end of the motor to open the housing and show the piston: |

|

Take

the hex screw out of the pump casing and turn the counter weight

to revel the hex screw in the counter weight - loosen it It takes a bit of work but lever the counterweight and piston off the motor shaft with a long screw driver down through the top. Take it out through the front cover hole. |

|

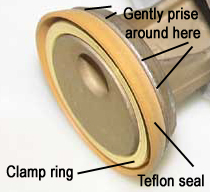

This

is the most important step!!! This picture shows your old piston fitted with a new Teflon seal. The Teflon seal is held in place between the piston and the clamp ring. Have a look at the new Teflon seal, you will notice that the clamp ring overlaps the Teflon seal by about 4mm to hold it in place. First, cut away as much of the old Teflon seal as you can see, you will then notice remains of the old Teflon seal trapped between the piston and the clamp ring. Using a sharp Stanley blade cut between the piston and the clamp ring, digging and cutting at the remains of the old ring until you have removed it all. You should then have a nice clean gap between the piston and the clamp ring about the thickness of the Teflon seal & about 4mm deep. Using a spatula, or similar, now wedge between the piston and clamp ring (in the gap you've just made), gently, and slowly work around the edge, prising at the clamp ring until it comes off. Try not to do too much damage to the piston or clamp ring as these are re-usable parts. Clean up any burr's or sharp edges you have caused as these burr's may cut or damage the new seal. Place the new seal and the old clamp ring onto the old piston and carefully tap down the clamp ring. The clamp ring should sit slightly lower then the top of the piston so use a large socket to help tap the clamp ring the rest of the way down. |

|

When

putting the cylinder back over the piston ring, be VERY

CAREFUL

not to put it straight over or you will tear and destroy the

Teflon piston ring. Putting the cylinder over the side from

an angle is easy and safe. Also pay attention to the orientation

of the cylinder, it has a lip which mates up with the groove on

the bottom of the cylinder head where you fitted the large O-ring. If the cylinder does not go on easily, push it down further at the angle before straightening it. It should go smoothly and easily when you have it right. If you have to force it something is wrong and you WILL tear the seal if you try to force it. |

|

Put

it all back together the same way it came apart: |

|